Key Takeaways

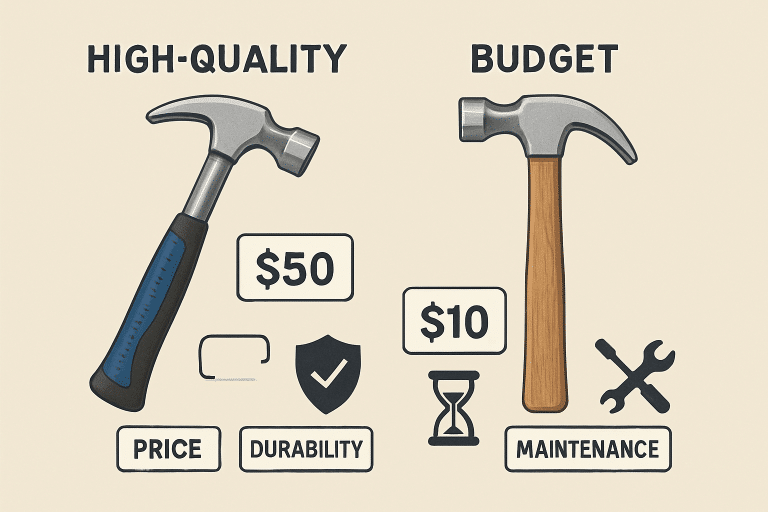

- Choosing between premium and budget tools impacts your upfront investment and long-term results, safety, and maintenance costs.

- Project frequency, user expertise, and specific use scenarios should guide buying high-end or affordable tools.

What Drives the Choice Between Quality Tools and Budget Alternatives?

Tool buyers face a crossroads between investing in high-quality, often more expensive equipment and opting for cost-effective budget alternatives. The primary factors driving this decision include the intended frequency of use, the complexity of the task, the available budget, and the user’s experience. For example, a professional mechanic will have different requirements from a homeowner preparing for occasional repairs. The project’s scope also matters: large-scale or safety-critical work typically benefits from premium tools offering greater reliability and durability. Conversely, light or occasional use may not justify the cost of top-of-the-line equipment. Consulting reliable industry suppliers, like Cruco Mill & Industrial Supply North Carolina, helps buyers match tools to their needs without overspending. Careful research and comparing specifications, warranties, and user reviews can ensure that the chosen tools balance performance, safety, and value.

The True Cost of Ownership

A common pitfall when acquiring tools is focusing solely on the upfront price. Tool ownership costs include maintenance, necessary repairs, and eventual replacement. Premium tools often require higher initial investments, but their durability can reduce ongoing expenses compared to budget options, which sometimes wear out or fail more quickly. An illuminating Family Handyman article highlights the long-term savings and reduced downtime associated with higher-quality tools.

Replacement cycles further impact total costs. Inexpensive tools may appear to be bargains, but frequent purchases due to breakage or diminished performance can quickly outstrip the original savings. Factoring in the cost of lost productivity—especially in professional environments—reinforces the argument for investing in quality tools for mission-critical applications.

Performance and Reliability in Action

Reliable performance ensures safety and consistency in any project involving automotive repair, woodworking, or industrial work. The superior engineering and materials associated with premium brands result in more precise and trustworthy results. For example, a premium torque wrench maintains accuracy over time, reducing the risk of under- or over-tightening bolts, which could have safety implications.

Real-world examples abound: construction professionals often recount how investing in high-quality cordless drills or saws pays off with faster job completion and fewer breakdowns. However, hobbyists using cheaper tools may face frustration over malfunctions or limited capabilities.

Budget Tools: When Are They the Right Choice?

Budget tools have their place. They are often the sensible option for situations where use is infrequent, the stakes are low, or the work doesn’t demand maximum precision. Occasional DIYers, for instance, can benefit from less expensive alternatives when tackling minor household projects or repairs. However, it’s crucial to differentiate between price and value a well-reviewed budget tool from a reputable brand can outperform a low-tier premium one.

When considering budget tools, look for independent reviews and recommendations. Prioritize items that offer solid warranties, accessible replacement parts, and positive long-term user feedback. This approach minimizes risk and helps ensure you get the best return on your spending.

The Value Proposition of Premium Tools

Spending more on tools often brings tangible benefits superior craftsmanship, better ergonomic design, and advanced features such as precision calibration or impact resistance. Longevity is a major factor; investment-grade brands usually stand behind their products with comprehensive warranties and reliable customer service.

In professional or high-use settings, reducing failures and downtime provided by premium tools can translate into substantial savings and peace of mind. Reliable performance, fewer work interruptions, and a lower total cost of ownership over time offset the up-front costs.

Making the Decision: A Step-by-Step Framework

- Define your primary use case: frequency, skill level, and project complexity.

- Assess available budget for tools, including long-term operating expenses.

- Compare user reviews, brand reliability, and warranty options for quality and budget selections.

- Consider the potential impact of failure or downtime on your work or safety.

- Consult experts and reputable suppliers for personalized recommendations.

Balancing these factors equips buyers to invest wisely, avoiding the pitfalls of unnecessarily buying the cheapest option or overspending.

Striking the Balance for Optimal Results

Making an informed choice between quality tools and budget options is rarely a one-size-fits-all decision. The best investments are guided by honest assessments of needs, expected use, and willingness to shoulder long-term costs. When in doubt, seeking guidance from industry leaders can streamline the path to optimal resultsbridging the gap between value and performance for professionals and DIYers.